20 Ways How to Calibrate a Thermometer

Methods for Calibrating Thermometers:

How to Calibrate a Thermometer

Calibrating a thermometer ensures that it’s providing accurate readings, which is crucial for food safety, scientific experiments, or industrial applications. Inaccurate thermometers can lead to undercooked food, incorrect scientific measurements, or faulty industrial processes. Thankfully, calibrating your thermometer doesn’t have to be complicated, and there are a few easy methods you can use, depending on the type of thermometer you’re working with.

What is One Way to Calibrate a Thermometer.?

When you’re in the kitchen or handling any type of temperature-sensitive equipment, a calibrated thermometer is crucial. But how do you calibrate a thermometer.? One of the most common ways to calibrate a thermometer is by using the ice water method. It’s simple, inexpensive, and highly effective. This method is perfect for both digital thermometers and metal stem thermometers. It involves placing the thermometer in a glass of ice water and checking if it reads 32°F or 0°C. If it doesn’t, you can adjust it to match that temperature.

This method is particularly handy when you don’t have access to specialized tools like a Fluke calibration tool or other industrial-grade equipment. However, it’s essential to remember that thermometer calibration is required in food safety standards to ensure that your readings are accurate for food safety compliance. If you’re in the food industry, calibrating your thermometer regularly is not just a best practice; it’s a legal requirement. Food safety standards often mandate that thermometers used to check food temperatures are properly calibrated to prevent the risk of foodborne illnesses.

If you’re unsure about how to calibrate a meat thermometer using this method, make sure to check the manufacturer’s instructions and test your thermometer periodically. This will help ensure that it stays accurate for your food preparation and safety needs. By regularly calibrating your thermometer, you can be confident that your temperature readings are reliable, whether you’re checking meat temperature, water temperature, or room temperature.

Why is Thermometer Calibration Important.?

A calibrated thermometer plays a crucial role in a variety of settings, whether you’re cooking, in a medical environment, or working with sensitive industrial equipment. Without proper calibration, your thermometer can give inaccurate readings, leading to potential safety risks. For instance, an incorrect reading in the kitchen could result in undercooked food, which could lead to foodborne illnesses.

In the medical field, an inaccurate thermometer could give wrong readings for a patient’s temperature, which could lead to incorrect diagnosis and treatment. Calibration ensures that your thermometer’s readings are precise and aligned with established standards. Without thermometer calibration, your tool is essentially unreliable, and its usefulness diminishes significantly.

It’s also essential for industries that rely on accurate temperature readings. For example, Fluke calibration services provide a professional method of ensuring that all temperature measurement tools are working correctly, especially in industrial or laboratory settings. Additionally, certain temperature-sensitive products need exact measurements during transport, storage, and use.

As you can see, calibration isn’t just a recommendation — it’s a necessity. Without it, you’re leaving things up to chance, and that can be costly. Whether you’re using a NIST-certified thermometer or a basic kitchen thermometer, ensuring accurate readings is essential.

How to Calibrate a Digital Thermometer.?

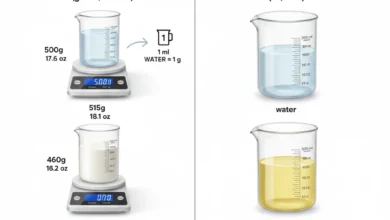

Calibrating a digital thermometer is a straightforward process, especially when using the ice water method. This process works similarly to other thermometers. Begin by filling a glass with crushed ice and adding cold water. Stir it well until you create an ice bath that stabilizes around the freezing point of water (32°F or 0°C).

Insert the digital thermometer into the ice water without letting it touch the sides or bottom of the glass. Wait for the thermometer to stabilize, and check the reading. If the thermometer doesn’t read 32°F (0°C), you’ll need to adjust it. Many digital thermometers come with a calibration adjustment feature that allows you to make changes easily.

This process ensures that your thermometer is accurately measuring temperature and will give you trustworthy results every time. If you need more advanced calibration services, you can reach out to companies offering thermometer calibration services for professionals. These services can handle more complex calibration needs, especially in industries that require traceable thermometer calibration or those that need to meet ISO 17025 thermometer calibration standards.

By calibrating your digital thermometer regularly, you ensure that it remains precise and reliable. Keeping a calibrated digital thermometer in your kitchen or workplace will give you confidence that your temperature measurements are accurate, which is crucial for health and safety.

Methods for Calibrating Thermometers:

The Ice Point Method for Thermometer Calibration

The ice point method is one of the most reliable and widely used techniques for thermometer calibration. It’s particularly beneficial because water has a well-established freezing point (32°F or 0°C) under standard atmospheric pressure, making it an ideal reference. This method is simple yet highly effective for both NIST calibrated thermometers and basic digital or analog thermometers.

To start, fill a glass with crushed ice and add enough water to cover the ice completely. Stir the mixture to ensure an even temperature throughout. Insert your thermometer into the center of the ice bath, ensuring it doesn’t touch the sides of the glass. Allow it to sit for a minute or two to stabilize. The thermometer should read 32°F or 0°C if it’s calibrated correctly. If it doesn’t, you’ll need to adjust it.

One of the reasons the ice point method is so widely used is that it’s simple, cost-effective, and can be performed anywhere. Even without access to Fluke calibration services, you can perform this calibration in your home kitchen, a restaurant, or a laboratory setting. However, in some cases, especially when traceable thermometer calibration is needed, it’s best to seek professional calibration services for precise measurements.

By routinely calibrating your thermometer using the ice point method, you can ensure that your thermometer remains accurate and reliable, reducing the risk of errors in both food safety and industrial measurements.

How Often Should You Calibrate a Thermometer.?

The frequency of thermometer calibration largely depends on how often and in what environment the thermometer is used. If you’re using your thermometer regularly, such as in a busy kitchen or laboratory, you’ll need to calibrate it more often. For instance, if you’re working with food, the HACCP process thermometer guidelines state that thermometers should be calibrated at least once a day. This ensures that your thermometer stays accurate and that your readings are reliable, which is essential for food safety.

If your thermometer is exposed to extreme conditions, like high heat or sudden temperature changes, you may need to calibrate it even more frequently. Some environments, such as industrial and laboratory settings, require thermometers to be calibrated at the beginning of every shift or before every use.

For less frequently used thermometers, calibration might only be necessary every few months, depending on the manufacturer’s recommendations. However, even if your thermometer is not used daily, it’s essential to check its calibration regularly to ensure it’s still reading accurately. This is especially true if you’re using NIST-certified thermometers or fluke thermometer calibration for high-precision measurements.

By maintaining a regular calibration schedule, you can extend the lifespan of your thermometer and ensure it continues to give accurate readings, which is critical in both medical and food safety settings.

The Role of a Certified Thermometer in Food Safety

In the food industry, having a certified thermometer is crucial. A calibrated thermometer ensures that you’re accurately measuring temperatures, which is vital to prevent the growth of harmful bacteria in food. For example, when cooking meat, the FDA thermometer calibration requirements state that thermometers used to check the internal temperature of meat should be calibrated regularly to ensure the meat reaches a safe cooking temperature.

If you work in a commercial kitchen, you might use a Fluke thermometer calibration service to ensure that your thermometers meet the highest accuracy standards. Calibration services help prevent errors that could compromise food safety. Plus, using a NIST-certified thermometer ensures you are following industry standards for temperature accuracy, which is important for passing food safety inspections.

A certified thermometer for calibration isn’t just important for regulatory reasons. It also helps you maintain the quality of your food. Whether you’re ensuring that the temperature probe is accurate when checking a steak or measuring the cold storage of perishables, an accurate thermometer plays a role in both food safety and quality assurance. For anyone working in the food industry, thermometer calibration is required in food safety standards to meet compliance and avoid serious health risks.

Ultimately, a calibrated temperature probe ensures your cooking, storage, and serving temperatures are just right, preventing undercooked or spoiled food. This is why regular calibration is critical to maintaining food quality and ensuring a safe environment for customers or family members.

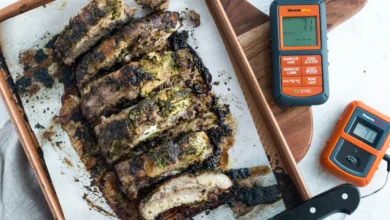

How to Calibrate a Meat Thermometer

How do you calibrate a meat thermometer? It’s a vital question for anyone in the food industry or even for home cooks who want to ensure the meat they’re serving is at a safe temperature. The process is relatively simple. One effective method is the boiling water method, which is ideal for checking if your meat thermometer is giving an accurate reading. To begin, bring a pot of water to a boil, and then insert your meat thermometer into the water, ensuring it doesn’t touch the sides of the pot. The thermometer should read 212°F (100°C) at sea level.

If your thermometer does not show the correct temperature, it’s time to calibrate meat thermometer either manually or by adjusting it according to the manufacturer’s instructions. If you use a Fluke 718 100G thermometer or similar, the calibration process can be completed with Fluke calibration services, ensuring the tool is functioning at its highest accuracy.

Remember, calibration isn’t a one-time task. It should be performed regularly to ensure that you’re always using an accurate thermometer. For meat preparation, especially, it’s crucial that your thermometer reads the correct temperature to avoid any risk of undercooking, which could lead to harmful bacteria growth. Whether you’re cooking ground beef, poultry, or steaks, keeping your thermometer calibrated ensures that every dish meets the food safety standards necessary for health.

The Ice Water Method for Thermometer Calibration

The ice water method is one of the most reliable techniques for calibrating a thermometer. It’s simple, cost-effective, and perfect for anyone working with thermometers for food safety, as well as for general use in various industries. To begin, fill a glass with crushed ice and add cold water until it covers the ice completely. Stir the mixture for a few minutes to ensure the temperature stabilizes at 32°F or 0°C, the freezing point of water.

Insert your thermometer into the ice bath, ensuring it does not touch the sides or bottom of the glass. Wait for the thermometer to stabilize and then check the reading. If it reads 32°F (0°C), your thermometer is calibrated. If it doesn’t, you’ll need to adjust it according to the manufacturer’s instructions.

This method is widely used because it’s easy to perform, doesn’t require expensive equipment, and offers excellent accuracy. For anyone using a digital thermometer or even a bimetallic thermometer, the ice point method provides a reliable calibration. Even though Fluke calibration services and professional-grade equipment like the Fluke 5502A can be used for more precise calibrations, the ice water method remains an excellent choice for everyday use, especially when you don’t have access to more advanced tools.

For those in the food industry, regular calibration using the ice water method ensures that you are following food safety standards and keeping your food at the right temperatures. Whether you’re cooking, storing, or transporting food, calibrating your thermometer accurately is essential to prevent foodborne illnesses.

Understanding the Importance of HACCP in Thermometer Calibration

The HACCP process is critical in maintaining food safety and ensuring that your thermometer calibration is aligned with the highest standards. HACCP (Hazard Analysis and Critical Control Points) outlines critical control points in food production, where specific risks must be addressed to prevent contamination or spoilage. Thermometer calibration plays a major role in this process.

As part of the HACCP process thermometer guidelines, thermometers must be calibrated regularly to ensure they measure food temperatures accurately. This is especially important for preventing the growth of harmful bacteria in high-risk foods like meats, poultry, and dairy products. Calibrating your thermometer according to HACCP standards means your food is being handled safely, which helps to avoid health violations and potential fines during food safety inspections.

Many businesses rely on thermometer calibration services that are tailored for HACCP compliance. These services help ensure that your thermometer is consistently accurate, reducing the risk of contamination. Using certified thermometers and adhering to the HACCP guidelines ensures that the right temperatures are maintained, preventing foodborne illness and maintaining public health.

For individuals working in food safety, the HACCP process and thermometer calibration go hand in hand to ensure that safe food practices are followed. Regular calibration checks help you stay compliant with food safety regulations, giving you confidence that you are offering the highest standard of food preparation and storage.

The Role of Professional Thermometer Calibration Services

While there are several DIY methods to calibrate thermometers, professional thermometer calibration services provide a higher level of accuracy and reliability, especially in high-stakes environments like laboratories or industrial settings. These services use specialized equipment and techniques, such as Fluke calibration tools, to ensure that your thermometer is calibrated to exact standards.

For instance, Fluke 5502A is a popular model used by calibration professionals for multimeter temperature probes and thermocouple calibrators. These precision tools are designed to give you highly accurate readings, especially when you’re calibrating thermometers in settings that require a high degree of accuracy.

Professional calibration services offer traceable thermometer calibration, meaning your thermometer calibration can be traced back to national or international standards. This is especially important for industries that need to meet strict quality assurance requirements, such as NIST thermometer certification.

Whether you need to calibrate a meat thermometer or an industrial infrared thermometer, professional services ensure that your tools are accurately calibrated and meet the required standards. When accuracy is critical — like in laboratories, medical devices, or food safety settings — trusting professionals for your calibration needs is always a good decision.

How to Calibrate an Infrared Thermometer

Calibrating an infrared thermometer can feel a little intimidating, but trust me, it’s pretty simple once you get the hang of it. Here’s the deal: infrared thermometers are super handy, but they can give you off readings if they aren’t calibrated correctly. So, what’s the best way to check that? A common method is using a calibrated temperature probe or something like a dry well calibrator.

Here’s how you do it: grab a temperature reference thermometer, like a Fluke 561 thermometer, and compare it with your infrared thermometer. It’s best to keep both at a fixed distance from whatever you’re measuring. Check to make sure both the reference and infrared thermometers are showing the same temperature. If they’re not, it’s time to adjust. Easy enough, right?

If you need really precise results (say, you’re in a lab or industrial setting), it’s probably best to get Fluke calibration services involved. They’ve got the tools to make sure everything is perfect.

And for anyone in the food industry — like me — calibrating your infrared thermometer isn’t just a good idea; it’s part of thermometer calibration is required in food safety standards. If your thermometer’s off, you might end up serving undercooked food, and that’s a big no-no. So, keep your calibration game strong, and you’ll always be on top of your temperature readings.

When Should You Calibrate Your Thermometer.?

It’s easy to forget when to calibrate your thermometer, but trust me — this is something you don’t want to ignore. The general rule of thumb is that if you use it often, calibrate it often. For example, in a busy kitchen or a food safety environment, it’s smart to calibrate your thermometer every day, before you start using it. Especially for meat thermometers, since you’re measuring something so important to health and safety.

If you’re working with Fluke calibration tools or NIST-certified thermometers in more industrial settings, you might need to calibrate before each use, especially if they’ve been exposed to extreme temperatures or dropped. It’s all about making sure your thermometer gives you those accurate readings every time.

Here’s the deal: thermometers are a bit like cars. They need a regular check-up. If you’re using them in harsh environments or in places where precision matters (like in a lab or for medical equipment), don’t wait too long to recalibrate. It’s always better to be safe than sorry, and a quick calibration every few months can save you from making a big mistake.

The Boiling Water Method for Thermometer Calibration

Okay, if you’re ever in a pinch and need a quick thermometer calibration, the boiling water method is your friend. It’s super easy and works for pretty much every type of thermometer — digital, bimetallic, or metal stem thermometers.

Here’s how it works: you simply bring a pot of water to a boil. Then, pop your thermometer in, making sure it doesn’t touch the sides or bottom of the pot. Your thermometer should read exactly 212°F (100°C) at sea level. If it doesn’t, it’s time to adjust it. It’s as simple as that.

This method is great because it’s effective and doesn’t require fancy tools. If you’re in the kitchen and need to calibrate a meat thermometer, for instance, this is an easy way to make sure it’s good to go. And it’s especially handy for anyone following food safety regulations. Calibration is key to making sure your meat is cooked properly, and this method gives you peace of mind.

But if you’re working in a more high-stakes environment (like a laboratory or industrial setting), it’s still a good idea to go for more precise services, like Fluke 5502A calibration, to make sure everything’s dialed in perfectly.

The Importance of NIST-Certified Thermometers

I can’t stress enough how valuable NIST-certified thermometers are, especially if you need absolute accuracy. These thermometers are calibrated against national standards, so you know they’re on point. And in fields like food safety, medical diagnostics, or even industrial work, it’s not just a suggestion — it’s a requirement.

Let’s talk about food safety for a second. When you use a NIST-calibrated thermometer to measure your meat’s internal temperature or check how cold your fridge is, you’re meeting the gold standard. And when you work in an environment where thermometer calibration is required in food safety standards, like restaurants or commercial kitchens, this is absolutely crucial.

It’s also important to keep in mind that Fluke calibration services can help maintain that NIST certification. That means you can count on your thermometer to deliver precise readings, no matter what environment you’re using it in. Whether you’re calibrating a meat thermometer or an industrial infrared thermometer, using a NIST-certified thermometer ensures that you’re on top of your game and compliant with the highest standards.

In short, if you want your thermometer to be trusted for critical readings, NIST certification is a must.

How to Choose the Right Calibration Method for Your Thermometer

Choosing the right calibration method can feel overwhelming, but it really depends on the kind of thermometer you’re using and the kind of accuracy you need. If you’re just working with a basic thermometer for everyday kitchen use, the boiling water method or ice water method will probably do the trick. Simple and effective.

But what if you’re using something more specialized? If you’re using Fluke calibration tools or even Fluke 5502A for industrial or laboratory-grade thermometers, then you’ll need to consider more precise methods, like dry well calibration. These methods are essential for getting those high-precision readings that NIST-certified thermometers provide.

And let’s not forget that sometimes, thermometer calibration needs to be traceable, especially in regulated industries. For example, if you’re calibrating a thermometer for food safety or medical purposes, you may need to rely on professional services to ensure everything is perfectly aligned with national standards.

So, whether you’re checking the temperature of a steak or calibrating a multimeter temperature probe in an industrial setting, choosing the right method will keep things running smoothly. Don’t hesitate to go professional if you need precision. After all, your thermometer is only as good as its calibration.

The Ice Water Method for Thermometer Calibration

If you’ve never tried the ice water method, let me tell you, it’s one of the easiest ways to check if your thermometer is still working like it should. Here’s what you do: grab a glass, fill it with crushed ice, and then pour just enough cold water to fill the gaps. Give it a stir to make sure the temperature is evenly distributed. Next, stick your thermometer into the glass — but don’t let it touch the sides or bottom. You want to make sure it’s just in the ice water, not resting on the glass itself.

Now, here’s where it gets interesting: Your thermometer should read exactly 32°F (0°C). If it doesn’t, you know it’s time to calibrate. It’s like a quick reality check to make sure your thermometer is on the money. The ice water method works so well because water freezes at exactly the same temperature, and it’s something you can do anywhere — no fancy tools or services needed.

This method is great for home cooks or small-scale operations, especially when you don’t have a Fluke 5502A or access to Fluke calibration services. It’s perfect for calibrating a meat thermometer or ensuring your thermometer used in food safety is still giving you accurate readings. As long as you make this part of your routine, you’ll know your thermometer is doing its job, and you’re keeping things safe.

When Should You Calibrate a Food Thermometer.?

So, when do you actually calibrate your food thermometer? The short answer: regularly. You don’t want to be caught off guard by inaccurate readings. Whether you’re measuring the temperature of that juicy steak or the roast chicken, your thermometer needs to be spot-on every time. For the best results, I recommend calibrating it before each use, especially if you’re preparing food for others. It takes just a minute and can make all the difference in food safety.

For those of us working in food-related jobs, like chefs or catering businesses, it’s not just a suggestion — thermometer calibration is required in food safety standards. And trust me, it’s there for a reason. Undercooked food, especially meat, can lead to foodborne illnesses. That’s why making sure your food thermometer is calibrated, whether using the ice water method or a more advanced service, is key to maintaining health and safety. You can always rely on professional thermometer calibration services if you need a little extra precision, especially if you’re working with Fluke calibration tools.

But even if you’re cooking at home, calibrating before you cook is always a good habit. I personally find the ice water method to be super convenient — it’s quick and doesn’t require anything special. Just make it a routine, and you’ll always feel confident in your thermometer’s readings.

Can You Calibrate Your Thermometer Without Special Tools.?

You might think that to calibrate a thermometer, you need to have fancy tools or expensive services. But here’s the thing — you can definitely calibrate a thermometer without special tools, and it’s actually pretty easy! For example, the boiling water method or ice water method are both simple and effective ways to calibrate a thermometer without needing anything fancy.

I’ve done it myself plenty of times, especially when I just need a quick check. The boiling water method is my go-to. All you need is a pot of water, bring it to a boil, and then place your thermometer in the water. It should read 212°F (100°C) at sea level, and if it doesn’t, you know it’s time to make an adjustment. It works for bimetallic thermometers and digital thermometers, and best of all — it’s free!

Of course, if you’re looking for precision, Fluke calibration services or using a NIST-certified thermometer are always the gold standard, but for everyday use, these DIY methods are more than enough. If you’re just calibrating a meat thermometer or checking the fridge temperature, the boiling water method is totally sufficient. It’s all about knowing when to get the right tools for the job.

Why You Should Keep Your Thermometer Calibrated Regularly

I can’t stress this enough: keeping your thermometer regularly calibrated is one of the easiest ways to make sure your readings are always accurate, and that’s super important. Think about it — if you don’t calibrate your thermometer regularly, you could be making decisions based on wrong information. Whether you’re cooking, storing food, or measuring temperatures for any other purpose, inaccurate readings can lead to mistakes that could have been avoided.

For anyone using a Fluke thermometer or any NIST-certified thermometer, calibration is absolutely necessary, and it doesn’t hurt to do it more often. For instance, thermometers in food settings (like meat thermometers) need to be calibrated at least once a day, especially before checking the temperatures of food. This isn’t just to make sure your food is cooked properly — it’s also to comply with food safety standards, which require calibrated tools to prevent foodborne illnesses.

Regular calibration is also an easy way to extend the life of your thermometer. If you take care of it, it’ll keep working for a long time. So, take that extra minute to check your thermometer’s accuracy, and you’ll avoid future headaches. Plus, you’ll have peace of mind knowing that you’re always working with accurate data.

How Often Should You Calibrate Your Infrared Thermometer.?

Now, if you’re using an infrared thermometer, you might be wondering, “How often should I calibrate this thing?” It’s an important question, and the answer depends on how much you’re using it. Infrared thermometers are incredibly handy, especially for measuring surface temperatures without making contact, but they can lose accuracy over time or with heavy use.

For general use, calibrate your infrared thermometer every few months. If you’re using it heavily — in a kitchen, industrial setting, or laboratory, for example — you should calibrate it more frequently. The Fluke 62 Max infrared thermometer is a popular model, and it’s one of the best when it comes to keeping your measurements consistent. But even top-tier equipment needs calibration to maintain its accuracy.

You can perform basic calibration using the boiling water method or the ice water method, or you could rely on Fluke calibration services if you need more precision. But regardless of the method, regular calibration is key to keeping your infrared thermometer working at its best.

FAQs:

1. How often should I calibrate my meat thermometer.?

You should calibrate your meat thermometer at least once a day, especially before use. This is particularly important when preparing food that needs to be cooked at precise temperatures. If you’re using it in a food safety setting, calibrating before every use is a good idea to avoid any mishaps.

2. Can I calibrate my thermometer without special tools.?

Absolutely! The ice water method and boiling water method are both great DIY methods that don’t require any special tools. Just grab some ice or boil some water, and you’re good to go. If you need more precise results, professional calibration services like Fluke calibration are available.

3. Why is it important to calibrate a thermometer regularly.?

Regular calibration ensures that your thermometer gives accurate readings every time. This is crucial for food safety, especially when you’re measuring things like meat temperatures. It helps prevent undercooking, which could lead to foodborne illnesses, and ensures you’re following food safety standards.

4. How do I know if my thermometer is off?

You can check your thermometer by using the ice water method or boiling water method. If the reading doesn’t match the expected value (32°F or 0°C for ice water, 212°F or 100°C for boiling water), then it’s time to calibrate it.

5. What are the best methods for calibrating a thermometer.?

Two of the most common methods are the ice water method and the boiling water method. For more precision, especially in industrial or laboratory settings, consider using Fluke calibration services or other professional calibration tools.

6. Can infrared thermometers be calibrated.?

Yes, infrared thermometers can absolutely be calibrated. You can use the boiling water method or dry well calibrators to ensure they are accurate. Calibration is especially important if you’re using it in critical environments like medical or food industries.

7. How often should I calibrate my infrared thermometer.?

For infrared thermometers, calibrate them every few months, or more frequently if used regularly in harsh environments. Calibration ensures the thermometer continues to give accurate surface temperature readings, which is crucial for industries like food preparation.

8. How can I calibrate a thermometer without a standard calibration tool.?

If you don’t have access to a professional calibration tool, the ice water method or boiling water method are easy and effective. For more precise calibration, though, consider using a certified thermometer or professional calibration services like Fluke calibration.

9. What temperature should my thermometer read for calibration.?

If you’re using the ice water method, your thermometer should read 32°F (0°C). For the boiling water method, it should read 212°F (100°C) at sea level. Make sure to adjust for elevation if necessary.

10. Is it necessary to calibrate a thermometer if it’s only used occasionally.?

Even if you don’t use your thermometer every day, it’s still a good idea to calibrate it periodically. Temperature readings can drift over time, and you want to be sure it’s accurate when you do need it. For meat thermometers, calibrate them before every use for peace of mind.

Conclusion

To wrap things up, calibrating a thermometer isn’t as complicated as it may seem, and it’s absolutely crucial for maintaining safety, accuracy, and reliability — whether you’re cooking at home, working in a food business, or managing industrial or medical equipment. By regularly calibrating your thermometer, you ensure that you’re always working with trustworthy data, preventing mistakes that could compromise food safety or even affect your business operations.

Whether you’re using the ice water method, the boiling water method, or relying on Fluke calibration services, the key takeaway is this: Calibration keeps your thermometer in top shape. It’s quick, simple, and should be part of your regular routine. So, next time you grab your thermometer, remember to give it a quick check to make sure it’s accurate. Trust me, the extra step is well worth it for peace of mind and safety.

Stay safe, stay accurate, and happy calibrating!